Product Description

Product Description

We can supply Jaw coupling, PF coupling, MC/MCT coupling, KX/KXT coupling, F-FLEXBLE coupling, HRC coupling, Chain coupling, NM coupling, MH coupling, Adjustble spacer coupling, Fenaflex coupling, Shaft coupling, Rigid coupling, Pin coupling.

With top quality, competitive price and prompt delivery, welcome your inquiry, thank you!

Detailed Photos

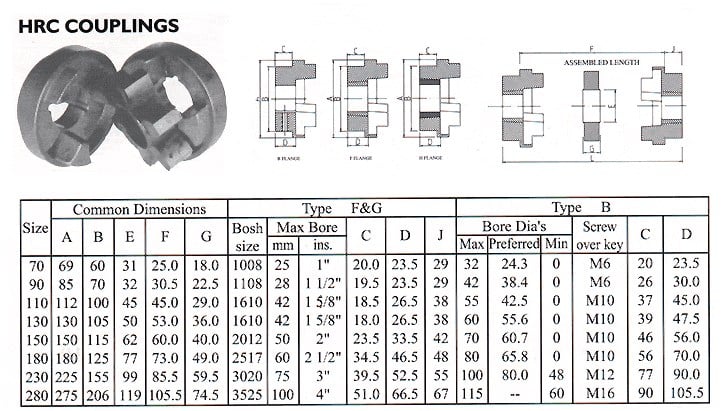

Product Parameters

|

After-sales Service |

Yes |

|

Warranty |

1 Year |

|

Connection |

Press Connection |

|

Structure |

Roller Chain |

|

Flexible or Rigid |

Flexible |

|

Material |

Carbon Stee |

|

Standard |

Standard |

| Port |

ZheJiang |

| Package |

Polywood Case |

| Payment | L/C, T/T, D/P, Western Union |

Our Advantages

Company advantages:

Own Import & Export License, The TV trade mark registered successfully in many countries, Sales network spread all over China, Products export to 65 countries in 5 continents.

Membership:

1. The member of China General Machine Components Industry Association.

2. The member of China Chain Transmission Association.

3. The member of China Chain Standardization Association.

4. The member of China Agricultural Association Machinery Manufacturers.

With our excellent trained staffs and workers, advanced and efficient equipments, completely sales network, strict QA systems. You are confidence that our premium qualified chain can meet all customers’ specification and strictest quality standards.

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years.

FAQ

Q1: What’s your average lead time?

A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate.

Q2: Is your price better than your competitors given the same quality?

A: Definitely YES. We provide the most competitive price in the power transmission industry. If price disparity exists, we’ll be more than happy to do a price match.

Q3: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q4: Can we inspect the goods before shipment?

A: Yes. You or your representative or any third-party inspection party assigned is allowed access to our facility and do the inspection.

Q5: What kind of payment method is acceptable for your mill?

A: We’re flexible. We take T/T, L/C, or any other online payment methods so long as it’s applicable for you.

Q6: What if I have any other questions?

A: Whenever in doubt, you’re always encouraged to consult our sales associate any time – They will help you to your satisfaction.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-32 |

| Torque: | >80N.M |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can HRC Couplings Accommodate High Torque and High-Speed Applications?

HRC (Highly Resilient Coupling) couplings are designed to handle a wide range of torque and speed requirements, making them suitable for various industrial applications, including those involving high torque and high-speed conditions. Their ability to accommodate high torque and high-speed applications depends on several factors:

- Coupling Size and Type: HRC couplings come in various sizes and types, each with its torque and speed ratings. Larger couplings with robust designs can handle higher torque and speed than smaller ones.

- Material Composition: HRC couplings consist of a metal hub and a flexible elastomeric element. The material composition of the elastomer plays a significant role in determining the coupling’s torque and speed capabilities.

- Elastomer Properties: The elastomeric element in HRC couplings provides flexibility and damping. It should be selected based on its resilience, durability, and ability to withstand the intended torque and speed requirements.

- Application Requirements: The coupling’s torque and speed ratings must match or exceed the demands of the application. Factors such as the driven and driving equipment’s power, load characteristics, and operational conditions should be considered.

- Proper Installation: Correct installation, including accurate alignment and proper torqueing of the coupling, ensures optimal performance and minimizes the risk of premature failure in high torque and speed applications.

It’s important to consult the manufacturer’s specifications and guidelines to select the appropriate HRC coupling for a specific high torque and high-speed application. Using an undersized or unsuitable coupling can lead to premature wear, reduced efficiency, and potential safety hazards.

In summary, HRC couplings are well-suited for high torque and high-speed applications when properly selected, installed, and maintained. They offer the benefits of damping vibrations, shock absorption, and misalignment compensation while reliably transmitting power in demanding industrial settings.

Factors to Consider When Choosing an HRC Coupling for a Specific System

When selecting an HRC coupling for a specific system, several crucial factors should be taken into consideration to ensure optimal performance and reliability:

1. Torque and Power Requirements: Determine the torque and power requirements of the application. This will help in selecting an HRC coupling with the appropriate torque rating and power capacity to handle the load.

2. Shaft Sizes: Check the shaft sizes of the connected equipment. The HRC coupling’s bore size should match the shaft sizes to ensure a proper fit and secure connection.

3. Misalignment Tolerance: Evaluate the expected misalignment in the system. HRC couplings are known for their ability to handle angular, parallel, and axial misalignment to a certain degree. Choose a coupling with the appropriate misalignment tolerance for your application.

4. Operating Speed: Consider the operating speed of the machinery. High-speed applications may require specially designed HRC couplings with balanced construction to prevent vibrations and maintain smooth operation.

5. Operating Temperature: Determine the range of operating temperatures in the system. Ensure that the selected HRC coupling can withstand the temperature extremes of the application without compromising its performance.

6. Environmental Conditions: Consider the environmental conditions in which the HRC coupling will operate. Factors such as moisture, dust, and corrosive elements should be taken into account when choosing the appropriate material and coating for the coupling.

7. Space Limitations: Evaluate the available space for the coupling installation. HRC couplings come in various sizes and designs, so choose one that fits within the spatial constraints of the system.

8. Maintenance Requirements: Determine the desired level of maintenance for the coupling. Some HRC couplings are maintenance-free, while others may require periodic inspection and lubrication.

9. Coupling Type: Consider the specific type of HRC coupling that best suits the application. HRC couplings are available in different designs, such as flange, taper bush, and pilot bore, each with its advantages for specific applications.

10. Budgetary Constraints: Finally, consider the budget for the coupling. While cost is an important factor, it should be balanced with the coupling’s performance, durability, and suitability for the application.

By carefully evaluating these factors, you can choose the most appropriate HRC coupling for your specific system, ensuring smooth power transmission, longevity, and reliability of your equipment.

Selection of HRC Coupling for Specific Applications

Choosing the appropriate HRC coupling for a specific application requires careful consideration of several factors. Here are the steps to select the right HRC coupling:

- Identify Application Requirements: Understand the specific requirements of your application, including torque and speed requirements, operating environment, shaft misalignment, and space limitations.

- Calculate Torque and Speed: Determine the torque and speed values required for your application. This information will help you select an HRC coupling that can handle the expected load and rotational speed.

- Consider Misalignment: Evaluate the type and magnitude of misalignment that the coupling needs to accommodate. HRC couplings can handle angular, parallel, and axial misalignment to varying degrees, so choose a design that meets your misalignment needs.

- Check Space Constraints: Consider the available space for the coupling. If space is limited, you may need a compact HRC design or consider other coupling types that require less space.

- Choose Hub Material: Select the hub material based on the application environment. Standard HRC hubs are usually made of cast iron, but stainless steel or other materials may be necessary for corrosive or specialized applications.

- Explore Design Variations: Evaluate the various HRC coupling designs available, such as standard, spacer, flywheel, taper lock, brake drum, etc. Choose a design that best suits your application’s needs.

- Consider Environmental Factors: If your application operates in harsh conditions, consider factors such as temperature, moisture, chemicals, and potential contamination when choosing the HRC coupling.

- Check Installation and Maintenance: Consider the ease of installation and maintenance requirements of the selected HRC coupling. Some designs, such as taper lock or pilot bore, offer easier installation and removal.

- Consult Manufacturer Recommendations: Consult with the coupling manufacturer or a knowledgeable supplier to ensure you select the right HRC coupling for your specific application. They can provide valuable insights and recommendations based on their expertise.

By carefully evaluating these factors and selecting the appropriate HRC coupling, you can ensure optimal performance, reliability, and longevity for your mechanical system.

editor by CX 2024-03-09

by

Leave a Reply